Started 05/29/2005 finished 01/19/2006 Finished.

Hours worked this chapter :139.5 Holding off on running the brake

lines until the nose is complete where the lines connect to the brakes

master cylinders.

Start this chapter by adding Landing Gear reinforcement lay

up.

In

this picture you can see I have already drilled the torque tube holes in the

landing gear bulk head. After this lay up I knife trimmed the holes open.

In

this picture you can see I have already drilled the torque tube holes in the

landing gear bulk head. After this lay up I knife trimmed the holes open.

Inside

the Landing Gear bay.

Inside

the Landing Gear bay.

Firewall

and bulkhead lay up.

Firewall

and bulkhead lay up.

The

strut is glassed with the peel ply

The

strut is glassed with the peel ply

The

mess after the first lay up.

The

mess after the first lay up.

A

little 5 minutes epoxy and some Mc D straws taped in place.

A

little 5 minutes epoxy and some Mc D straws taped in place.

This

step was made easer by reading

Rick Maddy's builder

web site, he said lightly sanding the straws before hand which helps the

epoxy hold better. Thanks!

This

step was made easer by reading

Rick Maddy's builder

web site, he said lightly sanding the straws before hand which helps the

epoxy hold better. Thanks!

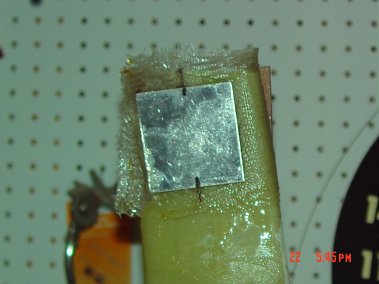

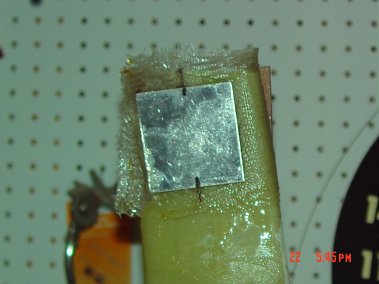

I

used the book method, which calls for aluminum foil taps the kind used on

air conditioning duck work. I had 6 layer of tap enough to make it good and

stiff.

I

used the book method, which calls for aluminum foil taps the kind used on

air conditioning duck work. I had 6 layer of tap enough to make it good and

stiff.

Ready

for the second lay up, you can see the Mc Donald's straws I used for the

brake line conduit.

Ready

for the second lay up, you can see the Mc Donald's straws I used for the

brake line conduit.

You

can just see the nails I used to hold the strut in place. As I have read in

other builders web sites they added a block of wood in increase the height

off the workbench. This was a great plus that I recommend. The strut is

covered with the second lay up and peel & ply.

You

can just see the nails I used to hold the strut in place. As I have read in

other builders web sites they added a block of wood in increase the height

off the workbench. This was a great plus that I recommend. The strut is

covered with the second lay up and peel & ply.

Strut

is set up in the jig box, glass cut ready to do the tabs.

Strut

is set up in the jig box, glass cut ready to do the tabs.

Marked

out the locations of the tabs on the jig box.

Marked

out the locations of the tabs on the jig box.

After

all this work the clamping was to aggressive and the layers slid during

cure. One thing about glass is that you can cut it off before it's

fully cured and do it again. Next time I will use one long board on each

side with less clamping pressure.

After

all this work the clamping was to aggressive and the layers slid during

cure. One thing about glass is that you can cut it off before it's

fully cured and do it again. Next time I will use one long board on each

side with less clamping pressure.

Second

time around was the charm.

Second

time around was the charm.

True

and parallel next I drilled the pilot holes and removed the jig box and cut

the tabs to proper size.

True

and parallel next I drilled the pilot holes and removed the jig box and cut

the tabs to proper size.

The

tabs are drilled and cut to proper size

The

tabs are drilled and cut to proper size

You

can see the 1/4 pilot hole, inside is sanded ready for the inside lay

up.

You

can see the 1/4 pilot hole, inside is sanded ready for the inside lay

up.

The

size of the glass was larger than needed as called for in the book, even

after I reduced the size by several inches it's still was a bit to much.

The

size of the glass was larger than needed as called for in the book, even

after I reduced the size by several inches it's still was a bit to much.

Inside

tab before trimming.

Inside

tab before trimming.

Here

is the inside tabs after trimming and sanding off any rough spots.

Here

is the inside tabs after trimming and sanding off any rough spots.

One

thing I learned was to make sure that each layer was dry, because as you add

layers the epoxy builds up and can make the lay up to epoxy rich. I used the

5 layer on wax paper process and made sure that there where dry spots which

would pull in any extra epoxy. Squeegee between each layer helps remove and

distribute the epoxy.

One

thing I learned was to make sure that each layer was dry, because as you add

layers the epoxy builds up and can make the lay up to epoxy rich. I used the

5 layer on wax paper process and made sure that there where dry spots which

would pull in any extra epoxy. Squeegee between each layer helps remove and

distribute the epoxy.

Here

are some shots of the plats with the 1/4 pilot hole. Floxed in place waiting

for cure.

Here

are some shots of the plats with the 1/4 pilot hole. Floxed in place waiting

for cure.

Once

the strut tabs where finished I bored out the plats as called out in the

book and mounted the bushings. Everything lined up, what a bit of luck, I

was kind of worried I had missed something. It would of bend very difficult

to fix.

Once

the strut tabs where finished I bored out the plats as called out in the

book and mounted the bushings. Everything lined up, what a bit of luck, I

was kind of worried I had missed something. It would of bend very difficult

to fix.

Final

tab lay up with bushings in place.

Final

tab lay up with bushings in place.

Fit

foam to fill the gap, macro in place, also you can see the dimpling on the MKMGA under the bid glass. Finished the tabs by trimming the excess glass now ready

test fit.

Fit

foam to fill the gap, macro in place, also you can see the dimpling on the MKMGA under the bid glass. Finished the tabs by trimming the excess glass now ready

test fit.

Here

you can see the laser level I used to make sure that the strut and axle

mounting hard point are level and true with the proper amount of toe in. The

toe in is very important this keeps the strut from splaying during landing

and normal operation. If you have to much toe in the wear on the wheels will

be excessive.

Here

you can see the laser level I used to make sure that the strut and axle

mounting hard point are level and true with the proper amount of toe in. The

toe in is very important this keeps the strut from splaying during landing

and normal operation. If you have to much toe in the wear on the wheels will

be excessive.

These

two picture show the wood used to make the flat area on the strut where the

axle will be located. In this step you make sure that the toe in is set.

After cure you can sand it during the fine tuning process.

These

two picture show the wood used to make the flat area on the strut where the

axle will be located. In this step you make sure that the toe in is set.

After cure you can sand it during the fine tuning process.

This

is the hard point on the inside of the strut.

This

is the hard point on the inside of the strut.

These

next two picture you can see the strut has been cut to accommodate the axle

and brake. You can also see the surface has been sanded to set the toe in

alignment.

These

next two picture you can see the strut has been cut to accommodate the axle

and brake. You can also see the surface has been sanded to set the toe in

alignment.

The

black outline is the axle base, I used it to make sure I removed just enough

of the strut for the brake.

The

black outline is the axle base, I used it to make sure I removed just enough

of the strut for the brake.

In

this picture show the axle is mounted and the toe in is checked again. At

this point you also fit and mount the brake system.

In

this picture show the axle is mounted and the toe in is checked again. At

this point you also fit and mount the brake system.

Wheel

and brakes mounted, I will finish the brake line and add the heat protection

later, most likely during assembly in the fuselage.

Wheel

and brakes mounted, I will finish the brake line and add the heat protection

later, most likely during assembly in the fuselage.

Test

fit and check of toe in using the laser and the tick marks on the door you

saw earlier.

Test

fit and check of toe in using the laser and the tick marks on the door you

saw earlier.

Strut

finished waiting to be mounted in fuselage. This will happen once the nose

gear is finished.

Strut

finished waiting to be mounted in fuselage. This will happen once the nose

gear is finished.

After

shaping the foam the NASA scoop area is glassed.

After

shaping the foam the NASA scoop area is glassed.

The

NASA scoop near the landing gear not yet shaped to the fuselage. (Camera

failure cause blur)

The

NASA scoop near the landing gear not yet shaped to the fuselage. (Camera

failure cause blur)

Cover

shaped and test landing gear fit.

Cover

shaped and test landing gear fit.

Cover

glassed with flox edges.

Cover

glassed with flox edges.

Screw

holes with counter sink finished.

Screw

holes with counter sink finished.

Starting

the speed brake removed from fuselage. Here I made it easer on myself by

take the suggestion from other builders web site and cute the glass while it

was still green, leaving some points to hold it in place.

Starting

the speed brake removed from fuselage. Here I made it easer on myself by

take the suggestion from other builders web site and cute the glass while it

was still green, leaving some points to hold it in place.

Here

I am testing the linear motor, I need to find the full cycle limits to

determine the location of the hard point. The hard point is made from 1/4

aluminum with a plywood face plate just like the hinge hard point called out

in the book for the hinge.

Here

I am testing the linear motor, I need to find the full cycle limits to

determine the location of the hard point. The hard point is made from 1/4

aluminum with a plywood face plate just like the hinge hard point called out

in the book for the hinge.

I

floxed in the hard point you can see the white dots are silicon plugs that

will prevent epoxy from entering the bolt holes. Once the 4 layer

reinforcement is cured I just drilled out the glass and then pick out the

plugs, it worked nice.

I

floxed in the hard point you can see the white dots are silicon plugs that

will prevent epoxy from entering the bolt holes. Once the 4 layer

reinforcement is cured I just drilled out the glass and then pick out the

plugs, it worked nice.

Here

is the finished inside. I got the Linear Actuator from

Firgelli-Automations.

Here

is the finished inside. I got the Linear Actuator from

Firgelli-Automations.

Here

are some picture of the finished outside, I made the wood insert 1/2 inch

wider than called for, glad I did.

Here

are some picture of the finished outside, I made the wood insert 1/2 inch

wider than called for, glad I did.

Here

are the parts for the landing bulk head cover. I used a paint can to

determine the size of the two holes. Not much detail in the book.

Here

are the parts for the landing bulk head cover. I used a paint can to

determine the size of the two holes. Not much detail in the book.

Installed

landing gear bulkhead, after cure I cut out the holes and remove some foam

from the edges of the hole to make room for some flox.

Installed

landing gear bulkhead, after cure I cut out the holes and remove some foam

from the edges of the hole to make room for some flox.

Landing

gear bulkhead covers.

Landing

gear bulkhead covers.

Landing

gear covers installed.

Landing

gear covers installed.

On to Chapter 10

In

this picture you can see I have already drilled the torque tube holes in the

landing gear bulk head. After this lay up I knife trimmed the holes open.

In

this picture you can see I have already drilled the torque tube holes in the

landing gear bulk head. After this lay up I knife trimmed the holes open. Inside

the Landing Gear bay.

Inside

the Landing Gear bay. Firewall

and bulkhead lay up.

Firewall

and bulkhead lay up. The

strut is glassed with the peel ply

The

strut is glassed with the peel ply The

mess after the first lay up.

The

mess after the first lay up. A

little 5 minutes epoxy and some Mc D straws taped in place.

A

little 5 minutes epoxy and some Mc D straws taped in place. This

step was made easer by reading

This

step was made easer by reading

I

used the book method, which calls for aluminum foil taps the kind used on

air conditioning duck work. I had 6 layer of tap enough to make it good and

stiff.

I

used the book method, which calls for aluminum foil taps the kind used on

air conditioning duck work. I had 6 layer of tap enough to make it good and

stiff. Ready

for the second lay up, you can see the Mc Donald's straws I used for the

brake line conduit.

Ready

for the second lay up, you can see the Mc Donald's straws I used for the

brake line conduit. You

can just see the nails I used to hold the strut in place. As I have read in

other builders web sites they added a block of wood in increase the height

off the workbench. This was a great plus that I recommend. The strut is

covered with the second lay up and peel & ply.

You

can just see the nails I used to hold the strut in place. As I have read in

other builders web sites they added a block of wood in increase the height

off the workbench. This was a great plus that I recommend. The strut is

covered with the second lay up and peel & ply. Strut

is set up in the jig box, glass cut ready to do the tabs.

Strut

is set up in the jig box, glass cut ready to do the tabs. Marked

out the locations of the tabs on the jig box.

Marked

out the locations of the tabs on the jig box. After

all this work the clamping was to aggressive and the layers slid during

cure. One thing about glass is that you can cut it off before it's

fully cured and do it again. Next time I will use one long board on each

side with less clamping pressure.

After

all this work the clamping was to aggressive and the layers slid during

cure. One thing about glass is that you can cut it off before it's

fully cured and do it again. Next time I will use one long board on each

side with less clamping pressure. Second

time around was the charm.

Second

time around was the charm. True

and parallel next I drilled the pilot holes and removed the jig box and cut

the tabs to proper size.

True

and parallel next I drilled the pilot holes and removed the jig box and cut

the tabs to proper size. The

tabs are drilled and cut to proper size

The

tabs are drilled and cut to proper size You

can see the 1/4 pilot hole, inside is sanded ready for the inside lay

up.

You

can see the 1/4 pilot hole, inside is sanded ready for the inside lay

up. The

size of the glass was larger than needed as called for in the book, even

after I reduced the size by several inches it's still was a bit to much.

The

size of the glass was larger than needed as called for in the book, even

after I reduced the size by several inches it's still was a bit to much.  Inside

tab before trimming.

Inside

tab before trimming. Here

is the inside tabs after trimming and sanding off any rough spots.

Here

is the inside tabs after trimming and sanding off any rough spots. One

thing I learned was to make sure that each layer was dry, because as you add

layers the epoxy builds up and can make the lay up to epoxy rich. I used the

5 layer on wax paper process and made sure that there where dry spots which

would pull in any extra epoxy. Squeegee between each layer helps remove and

distribute the epoxy.

One

thing I learned was to make sure that each layer was dry, because as you add

layers the epoxy builds up and can make the lay up to epoxy rich. I used the

5 layer on wax paper process and made sure that there where dry spots which

would pull in any extra epoxy. Squeegee between each layer helps remove and

distribute the epoxy. Here

are some shots of the plats with the 1/4 pilot hole. Floxed in place waiting

for cure.

Here

are some shots of the plats with the 1/4 pilot hole. Floxed in place waiting

for cure. Once

the strut tabs where finished I bored out the plats as called out in the

book and mounted the bushings. Everything lined up, what a bit of luck, I

was kind of worried I had missed something. It would of bend very difficult

to fix.

Once

the strut tabs where finished I bored out the plats as called out in the

book and mounted the bushings. Everything lined up, what a bit of luck, I

was kind of worried I had missed something. It would of bend very difficult

to fix. Final

tab lay up with bushings in place.

Final

tab lay up with bushings in place.  Fit

foam to fill the gap, macro in place, also you can see the dimpling on the MKMGA under the bid glass. Finished the tabs by trimming the excess glass now ready

test fit.

Fit

foam to fill the gap, macro in place, also you can see the dimpling on the MKMGA under the bid glass. Finished the tabs by trimming the excess glass now ready

test fit. Here

you can see the laser level I used to make sure that the strut and axle

mounting hard point are level and true with the proper amount of toe in. The

toe in is very important this keeps the strut from splaying during landing

and normal operation. If you have to much toe in the wear on the wheels will

be excessive.

Here

you can see the laser level I used to make sure that the strut and axle

mounting hard point are level and true with the proper amount of toe in. The

toe in is very important this keeps the strut from splaying during landing

and normal operation. If you have to much toe in the wear on the wheels will

be excessive.  These

two picture show the wood used to make the flat area on the strut where the

axle will be located. In this step you make sure that the toe in is set.

After cure you can sand it during the fine tuning process.

These

two picture show the wood used to make the flat area on the strut where the

axle will be located. In this step you make sure that the toe in is set.

After cure you can sand it during the fine tuning process.

This

is the hard point on the inside of the strut.

This

is the hard point on the inside of the strut. These

next two picture you can see the strut has been cut to accommodate the axle

and brake. You can also see the surface has been sanded to set the toe in

alignment.

These

next two picture you can see the strut has been cut to accommodate the axle

and brake. You can also see the surface has been sanded to set the toe in

alignment. The

black outline is the axle base, I used it to make sure I removed just enough

of the strut for the brake.

The

black outline is the axle base, I used it to make sure I removed just enough

of the strut for the brake. In

this picture show the axle is mounted and the toe in is checked again. At

this point you also fit and mount the brake system.

In

this picture show the axle is mounted and the toe in is checked again. At

this point you also fit and mount the brake system. Wheel

and brakes mounted, I will finish the brake line and add the heat protection

later, most likely during assembly in the fuselage.

Wheel

and brakes mounted, I will finish the brake line and add the heat protection

later, most likely during assembly in the fuselage.  Test

fit and check of toe in using the laser and the tick marks on the door you

saw earlier.

Test

fit and check of toe in using the laser and the tick marks on the door you

saw earlier. Strut

finished waiting to be mounted in fuselage. This will happen once the nose

gear is finished.

Strut

finished waiting to be mounted in fuselage. This will happen once the nose

gear is finished. After

shaping the foam the NASA scoop area is glassed.

After

shaping the foam the NASA scoop area is glassed. The

NASA scoop near the landing gear not yet shaped to the fuselage. (Camera

failure cause blur)

The

NASA scoop near the landing gear not yet shaped to the fuselage. (Camera

failure cause blur) Cover

shaped and test landing gear fit.

Cover

shaped and test landing gear fit. Cover

glassed with flox edges.

Cover

glassed with flox edges. Screw

holes with counter sink finished.

Screw

holes with counter sink finished. Starting

the speed brake removed from fuselage. Here I made it easer on myself by

take the suggestion from other builders web site and cute the glass while it

was still green, leaving some points to hold it in place.

Starting

the speed brake removed from fuselage. Here I made it easer on myself by

take the suggestion from other builders web site and cute the glass while it

was still green, leaving some points to hold it in place. Here

I am testing the linear motor, I need to find the full cycle limits to

determine the location of the hard point. The hard point is made from 1/4

aluminum with a plywood face plate just like the hinge hard point called out

in the book for the hinge.

Here

I am testing the linear motor, I need to find the full cycle limits to

determine the location of the hard point. The hard point is made from 1/4

aluminum with a plywood face plate just like the hinge hard point called out

in the book for the hinge. I

floxed in the hard point you can see the white dots are silicon plugs that

will prevent epoxy from entering the bolt holes. Once the 4 layer

reinforcement is cured I just drilled out the glass and then pick out the

plugs, it worked nice.

I

floxed in the hard point you can see the white dots are silicon plugs that

will prevent epoxy from entering the bolt holes. Once the 4 layer

reinforcement is cured I just drilled out the glass and then pick out the

plugs, it worked nice.  Here

is the finished inside. I got the Linear Actuator from

Here

is the finished inside. I got the Linear Actuator from

Here

are some picture of the finished outside, I made the wood insert 1/2 inch

wider than called for, glad I did.

Here

are some picture of the finished outside, I made the wood insert 1/2 inch

wider than called for, glad I did. Here

are the parts for the landing bulk head cover. I used a paint can to

determine the size of the two holes. Not much detail in the book.

Here

are the parts for the landing bulk head cover. I used a paint can to

determine the size of the two holes. Not much detail in the book. Installed

landing gear bulkhead, after cure I cut out the holes and remove some foam

from the edges of the hole to make room for some flox.

Installed

landing gear bulkhead, after cure I cut out the holes and remove some foam

from the edges of the hole to make room for some flox. Landing

gear bulkhead covers.

Landing

gear bulkhead covers. Landing

gear covers installed.

Landing

gear covers installed.