Matco master brake cylinders.

Here

you can see the strut temporally mounted on two screws on my work table top,

I used 5 min. epoxy. After the glass is cured a sharp rap on each screw

breaks the strut loose, worked out nicely.

Here

you can see the strut temporally mounted on two screws on my work table top,

I used 5 min. epoxy. After the glass is cured a sharp rap on each screw

breaks the strut loose, worked out nicely.

There

has been some issues with NG30 so I am following the design change

recommendations.

There

has been some issues with NG30 so I am following the design change

recommendations.

Cut

foam to new dimensions and started glassing pivot point for landing gear.

Cut

foam to new dimensions and started glassing pivot point for landing gear.

Marking

location for

EZ-Noselift hard points and the hard points for landing gear pivot floxed.

Marking

location for

EZ-Noselift hard points and the hard points for landing gear pivot floxed.

Glassing

inside with the additional bid strips.

Glassing

inside with the additional bid strips.

Glassing

out side with bid strips and hard points for power retraction system.

Glassing

out side with bid strips and hard points for power retraction system.

Hard

points used to mount the

EZ-Noselift hardware.

Hard

points used to mount the

EZ-Noselift hardware.

NG30

outside finished glass.

NG30

outside finished glass.

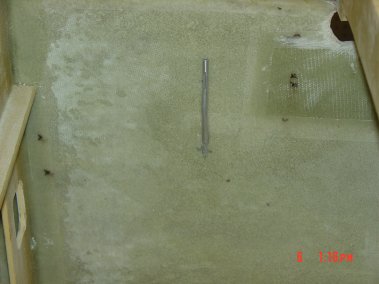

Removed

foam and glass inside of landing gear pivot location on NG30.

Removed

foam and glass inside of landing gear pivot location on NG30.

Flox

the strut to the pivot bearing making sure it is centered in between NG30s.

Flox

the strut to the pivot bearing making sure it is centered in between NG30s.

Clamp

until flox is cured.

Clamp

until flox is cured.

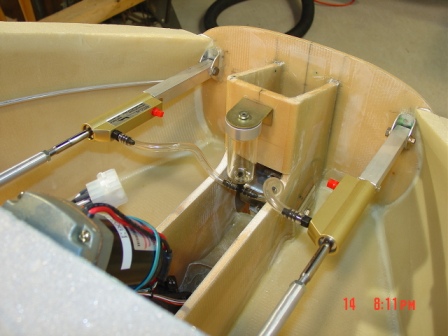

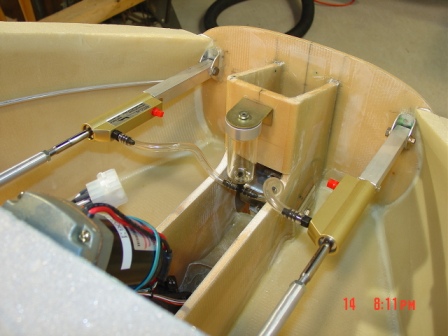

In

this picture you can see the 1/4" plate in front of the bearing and the

attachment point of the landing gear actuator.

In

this picture you can see the 1/4" plate in front of the bearing and the

attachment point of the landing gear actuator.

Test

fit of F0 with NG30, you can see the foam part f6 I am using the cut out

from the main spar access openings.

Test

fit of F0 with NG30, you can see the foam part f6 I am using the cut out

from the main spar access openings.

Glassed

F0 with NG30 assembly.

Glassed

F0 with NG30 assembly.

Mounting

NG30 to fuselage

Mounting

NG30 to fuselage

Carved

and added nose bottoms using thick macro.

Carved

and added nose bottoms using thick macro.

Glassed

bottom inside up to where the sides will attach, so you do not hit the glass

when carving the sides.

Glassed

bottom inside up to where the sides will attach, so you do not hit the glass

when carving the sides.

You

can see the glass runs on to the floor back past f22.

You

can see the glass runs on to the floor back past f22.

Nose

bulkhead glassed and peel ply.

Nose

bulkhead glassed and peel ply.

I

am using the ballast box location for my landing lights.

I

am using the ballast box location for my landing lights.

These

lights are 55w halogen each, focused beam. I used a tube bender to get the

pitot tube just right so it fits without being in the way of the lights and

is sloping up.

These

lights are 55w halogen each, focused beam. I used a tube bender to get the

pitot tube just right so it fits without being in the way of the lights and

is sloping up.

Sides

macro in place and inside glassed.

Sides

macro in place and inside glassed.

One

side required a little clamping pressure to hold in place for cure.

One

side required a little clamping pressure to hold in place for cure.

As

you can see I am going to have landing gear doors for the front wheel well.

As

you can see I am going to have landing gear doors for the front wheel well.

In

this picture you can see how the lights fit in the ballast box and the

bracket that will hold the brake fluid reservoir. I am using Matco master

cylinders.

In

this picture you can see how the lights fit in the ballast box and the

bracket that will hold the brake fluid reservoir. I am using Matco master

cylinders.

Foam

blocks build up for nose.

Foam

blocks build up for nose.

Inside

shot of wheel well opening.

Inside

shot of wheel well opening.

The

blue PVC foam is for the rudder pedals mounting hard point and the bottom of

the canard area. Also you can see the pitot and static tubes.

The

blue PVC foam is for the rudder pedals mounting hard point and the bottom of

the canard area. Also you can see the pitot and static tubes.

Velocity

rubber pedals, I will paint them before final installation.

Velocity

rubber pedals, I will paint them before final installation.

Opening

on each end is for the canard attachment tabs.

Opening

on each end is for the canard attachment tabs.

Static

tube floxed in place, marked the outside location to make it easer to drill

the 3 - 1/16th holes.

Static

tube floxed in place, marked the outside location to make it easer to drill

the 3 - 1/16th holes.

Made

a cardboard cover that fits the shape of the strut giving enough room for

any movement once installed.

Made

a cardboard cover that fits the shape of the strut giving enough room for

any movement once installed.

In

the back you can see the cardboard form and the finished strut cover. To the

left you can see the 1/8" hard board I used to match the cure of the strut.

Packing tape using to cover all allowing release.

In

the back you can see the cardboard form and the finished strut cover. To the

left you can see the 1/8" hard board I used to match the cure of the strut.

Packing tape using to cover all allowing release.

Strut

cover test fit.

Strut

cover test fit.

Wheel

well cover with the foam still inside waiting for the glass to cure.

Wheel

well cover with the foam still inside waiting for the glass to cure.

Window

added to wheel well cover on each side, used to view landing gear position.

Window

added to wheel well cover on each side, used to view landing gear position.

Started

shaping the sides.

Started

shaping the sides.

Finished

the side and bottom and floxed in the strut cover, weight down for cure.

Finished

the side and bottom and floxed in the strut cover, weight down for cure.

Finished

landing lights openings, I will use Lexan covers.

Finished

landing lights openings, I will use Lexan covers.

Glassed

bottom, you can see the pitot tube at the tip of the nose.

Glassed

bottom, you can see the pitot tube at the tip of the nose.

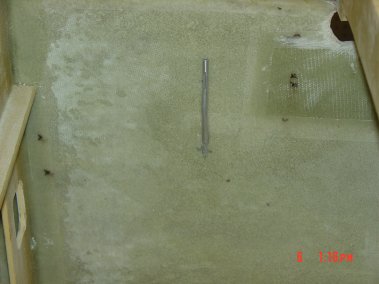

You

can see that the strut is not yet cut free, waited until glass got to knife

trim stage, then used a steel ruler as a straight edge. Came out real nice.

You

can see that the strut is not yet cut free, waited until glass got to knife

trim stage, then used a steel ruler as a straight edge. Came out real nice.

Nose

foam rough fit, ballast box glassed.

Nose

foam rough fit, ballast box glassed.

Foam

will be glued in place with 5 min. epoxy temporarily so that it can be

shaped and latter removed to glass the inside.

Foam

will be glued in place with 5 min. epoxy temporarily so that it can be

shaped and latter removed to glass the inside.

Took

my time with this step using the template created from the drawings,

starting to look good.

Took

my time with this step using the template created from the drawings,

starting to look good.

Access

doors glassed on nose to get a perfect fit.

Access

doors glassed on nose to get a perfect fit.

Access

door foam removed, nosed prepped. Glassing inside of doors then put back in

place to cure.

Access

door foam removed, nosed prepped. Glassing inside of doors then put back in

place to cure.

Glassing

inside of ballast access door. Placed back on nose to cure.

Glassing

inside of ballast access door. Placed back on nose to cure.

Nose

access door inside glassed, will be placed back on nose to cure.

Nose

access door inside glassed, will be placed back on nose to cure.

Nosed

is glassed and doors weighted down into recessed openings to cure.

Nosed

is glassed and doors weighted down into recessed openings to cure.

Used

sand bags to weight down doors during nose glassing.

Used

sand bags to weight down doors during nose glassing.

Nose

top removed to make it easer to work on the rudder peddles and breaks.

Nose

top removed to make it easer to work on the rudder peddles and breaks.

Brake

cylinder layout, Matco style. I used aluminum square stock to extend

from F0 the mounting brackets are floxed and bid taped in place.

Brake

cylinder layout, Matco style. I used aluminum square stock to extend

from F0 the mounting brackets are floxed and bid taped in place.

In

this picture you can see the rudder peddles and the stainless steel forks

that I purchased from Dale Rogers. I first saw this design on Brian DeFords

Cozy. "The actuator is threaded onto the end of the Matco

lay down master cylinder and has a slot wide enough for the rudder pedal to

slide within. A bolt is inserted thru the actuator and thru a hole in the

rudder pedal. As the pedal is compressed the bolt slides in a slot until it

reaches the end of the slot. Once the bolt hits the end of the slot the

master cylinder is then actuated by further pushing on the rudder pedal. The

slot is designed to allow the rudders to be fully deflected at the end of

the slot. The adjustable foot pegs can be seen in this view as well." (Brian

DeFord Web)

In

this picture you can see the rudder peddles and the stainless steel forks

that I purchased from Dale Rogers. I first saw this design on Brian DeFords

Cozy. "The actuator is threaded onto the end of the Matco

lay down master cylinder and has a slot wide enough for the rudder pedal to

slide within. A bolt is inserted thru the actuator and thru a hole in the

rudder pedal. As the pedal is compressed the bolt slides in a slot until it

reaches the end of the slot. Once the bolt hits the end of the slot the

master cylinder is then actuated by further pushing on the rudder pedal. The

slot is designed to allow the rudders to be fully deflected at the end of

the slot. The adjustable foot pegs can be seen in this view as well." (Brian

DeFord Web)

The

Matco master cylinders are now laying on their sides to make it easer to

connect to the reservoir.

The

Matco master cylinders are now laying on their sides to make it easer to

connect to the reservoir.

With

this set up I get more than the required peddle travel.

With

this set up I get more than the required peddle travel.

Glassed

inside top of the nose, the two small foam block in each side of the opening

is where the locking bars for the doors contact.

Glassed

inside top of the nose, the two small foam block in each side of the opening

is where the locking bars for the doors contact.

Nose

re-attached with flox and bid tape inside and out.

Nose

re-attached with flox and bid tape inside and out.

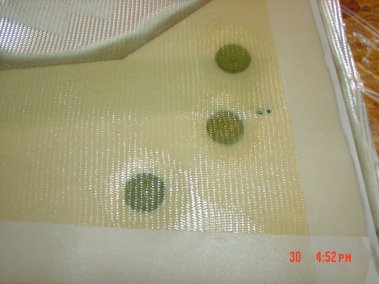

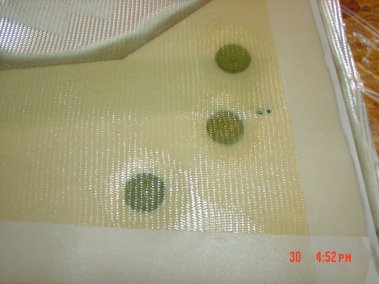

Glassed

the canard nose area with two ply of bid and flox corners all around. The

dark green spots are the rudder peddle hard points.

Glassed

the canard nose area with two ply of bid and flox corners all around. The

dark green spots are the rudder peddle hard points.

I

wanted to lock the nose access door rather then using screws as called for

in the plans, here is what I came up with, works good.

I

wanted to lock the nose access door rather then using screws as called for

in the plans, here is what I came up with, works good.

Purchased

two keyed alike barrel locks one for the nose and the second on will be used

to open the cockpit.

Purchased

two keyed alike barrel locks one for the nose and the second on will be used

to open the cockpit.

Here

is the locking mechanism I created for the main nose access door, showing

the locked position. The aluminum bar extend to catch the underside of the

nose compartment.

Here

is the locking mechanism I created for the main nose access door, showing

the locked position. The aluminum bar extend to catch the underside of the

nose compartment.

In

this picture the locking mechanism is in the open position, the bars retract

in the 90 degree turn of the key, works real smooth and holds the doors down

nice the tight.

In

this picture the locking mechanism is in the open position, the bars retract

in the 90 degree turn of the key, works real smooth and holds the doors down

nice the tight.

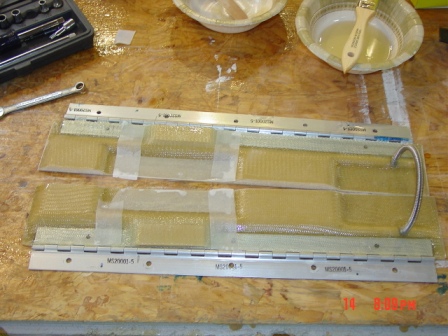

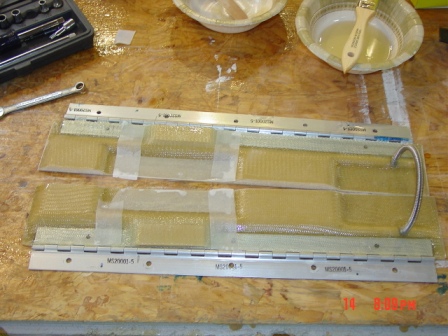

Landing

gear doors material outside glassed, the center line is where I will cut the

doors apart after installed on the hinges.

Landing

gear doors material outside glassed, the center line is where I will cut the

doors apart after installed on the hinges.

Nose

wheel doors with hinges glassed, removed excess foam for landing gear wheel

and strut.

Nose

wheel doors with hinges glassed, removed excess foam for landing gear wheel

and strut.

The

spring on the right hand side is used to close the doors when the landing

gear is retracted, got this idea from other buildings. Thanks

The

spring on the right hand side is used to close the doors when the landing

gear is retracted, got this idea from other buildings. Thanks

Two

strips of ply wood floxed in place with 5 threaded aluminum slugs on each

side. Ends of door opening floxed and glassed.

Two

strips of ply wood floxed in place with 5 threaded aluminum slugs on each

side. Ends of door opening floxed and glassed.

Floxed

doors in place weighted down.

Floxed

doors in place weighted down.

Testing

landing gear doors, the spring works great.

Testing

landing gear doors, the spring works great.

Wheel

well installed with flox and bid.

Wheel

well installed with flox and bid.

Return

spring mount for rudder peddle, one on each side.

Return

spring mount for rudder peddle, one on each side.

Finished on to Chap. 16, 17 & 24 want to complete as much of

the interior before it becomes impossible to lay the fuselage on its side.

Here

you can see the strut temporally mounted on two screws on my work table top,

I used 5 min. epoxy. After the glass is cured a sharp rap on each screw

breaks the strut loose, worked out nicely.

Here

you can see the strut temporally mounted on two screws on my work table top,

I used 5 min. epoxy. After the glass is cured a sharp rap on each screw

breaks the strut loose, worked out nicely. There

has been some issues with NG30 so I am following the design change

recommendations.

There

has been some issues with NG30 so I am following the design change

recommendations. Cut

foam to new dimensions and started glassing pivot point for landing gear.

Cut

foam to new dimensions and started glassing pivot point for landing gear. Marking

location for

EZ-Noselift hard points and the hard points for landing gear pivot floxed.

Marking

location for

EZ-Noselift hard points and the hard points for landing gear pivot floxed. Glassing

inside with the additional bid strips.

Glassing

inside with the additional bid strips. Glassing

out side with bid strips and hard points for power retraction system.

Glassing

out side with bid strips and hard points for power retraction system. Hard

points used to mount the

EZ-Noselift hardware.

Hard

points used to mount the

EZ-Noselift hardware. NG30

outside finished glass.

NG30

outside finished glass. Removed

foam and glass inside of landing gear pivot location on NG30.

Removed

foam and glass inside of landing gear pivot location on NG30. Flox

the strut to the pivot bearing making sure it is centered in between NG30s.

Flox

the strut to the pivot bearing making sure it is centered in between NG30s. Clamp

until flox is cured.

Clamp

until flox is cured. In

this picture you can see the 1/4" plate in front of the bearing and the

attachment point of the landing gear actuator.

In

this picture you can see the 1/4" plate in front of the bearing and the

attachment point of the landing gear actuator. Test

fit of F0 with NG30, you can see the foam part f6 I am using the cut out

from the main spar access openings.

Test

fit of F0 with NG30, you can see the foam part f6 I am using the cut out

from the main spar access openings. Glassed

F0 with NG30 assembly.

Glassed

F0 with NG30 assembly. Mounting

NG30 to fuselage

Mounting

NG30 to fuselage Carved

and added nose bottoms using thick macro.

Carved

and added nose bottoms using thick macro. Glassed

bottom inside up to where the sides will attach, so you do not hit the glass

when carving the sides.

Glassed

bottom inside up to where the sides will attach, so you do not hit the glass

when carving the sides. You

can see the glass runs on to the floor back past f22.

You

can see the glass runs on to the floor back past f22. Nose

bulkhead glassed and peel ply.

Nose

bulkhead glassed and peel ply.

I

am using the ballast box location for my landing lights.

I

am using the ballast box location for my landing lights.  These

lights are 55w halogen each, focused beam. I used a tube bender to get the

pitot tube just right so it fits without being in the way of the lights and

is sloping up.

These

lights are 55w halogen each, focused beam. I used a tube bender to get the

pitot tube just right so it fits without being in the way of the lights and

is sloping up.  Sides

macro in place and inside glassed.

Sides

macro in place and inside glassed. One

side required a little clamping pressure to hold in place for cure.

One

side required a little clamping pressure to hold in place for cure. As

you can see I am going to have landing gear doors for the front wheel well.

As

you can see I am going to have landing gear doors for the front wheel well. In

this picture you can see how the lights fit in the ballast box and the

bracket that will hold the brake fluid reservoir. I am using Matco master

cylinders.

In

this picture you can see how the lights fit in the ballast box and the

bracket that will hold the brake fluid reservoir. I am using Matco master

cylinders. Foam

blocks build up for nose.

Foam

blocks build up for nose. Inside

shot of wheel well opening.

Inside

shot of wheel well opening. The

blue PVC foam is for the rudder pedals mounting hard point and the bottom of

the canard area. Also you can see the pitot and static tubes.

The

blue PVC foam is for the rudder pedals mounting hard point and the bottom of

the canard area. Also you can see the pitot and static tubes. Velocity

rubber pedals, I will paint them before final installation.

Velocity

rubber pedals, I will paint them before final installation. Opening

on each end is for the canard attachment tabs.

Opening

on each end is for the canard attachment tabs. Static

tube floxed in place, marked the outside location to make it easer to drill

the 3 - 1/16th holes.

Static

tube floxed in place, marked the outside location to make it easer to drill

the 3 - 1/16th holes. Made

a cardboard cover that fits the shape of the strut giving enough room for

any movement once installed.

Made

a cardboard cover that fits the shape of the strut giving enough room for

any movement once installed. In

the back you can see the cardboard form and the finished strut cover. To the

left you can see the 1/8" hard board I used to match the cure of the strut.

Packing tape using to cover all allowing release.

In

the back you can see the cardboard form and the finished strut cover. To the

left you can see the 1/8" hard board I used to match the cure of the strut.

Packing tape using to cover all allowing release. Strut

cover test fit.

Strut

cover test fit. Wheel

well cover with the foam still inside waiting for the glass to cure.

Wheel

well cover with the foam still inside waiting for the glass to cure. Window

added to wheel well cover on each side, used to view landing gear position.

Window

added to wheel well cover on each side, used to view landing gear position. Started

shaping the sides.

Started

shaping the sides. Finished

the side and bottom and floxed in the strut cover, weight down for cure.

Finished

the side and bottom and floxed in the strut cover, weight down for cure. Finished

landing lights openings, I will use Lexan covers.

Finished

landing lights openings, I will use Lexan covers. Glassed

bottom, you can see the pitot tube at the tip of the nose.

Glassed

bottom, you can see the pitot tube at the tip of the nose. You

can see that the strut is not yet cut free, waited until glass got to knife

trim stage, then used a steel ruler as a straight edge. Came out real nice.

You

can see that the strut is not yet cut free, waited until glass got to knife

trim stage, then used a steel ruler as a straight edge. Came out real nice. Nose

foam rough fit, ballast box glassed.

Nose

foam rough fit, ballast box glassed.  Foam

will be glued in place with 5 min. epoxy temporarily so that it can be

shaped and latter removed to glass the inside.

Foam

will be glued in place with 5 min. epoxy temporarily so that it can be

shaped and latter removed to glass the inside. Took

my time with this step using the template created from the drawings,

starting to look good.

Took

my time with this step using the template created from the drawings,

starting to look good.

Access

doors glassed on nose to get a perfect fit.

Access

doors glassed on nose to get a perfect fit. Access

door foam removed, nosed prepped. Glassing inside of doors then put back in

place to cure.

Access

door foam removed, nosed prepped. Glassing inside of doors then put back in

place to cure. Glassing

inside of ballast access door. Placed back on nose to cure.

Glassing

inside of ballast access door. Placed back on nose to cure. Nose

access door inside glassed, will be placed back on nose to cure.

Nose

access door inside glassed, will be placed back on nose to cure. Nosed

is glassed and doors weighted down into recessed openings to cure.

Nosed

is glassed and doors weighted down into recessed openings to cure. Used

sand bags to weight down doors during nose glassing.

Used

sand bags to weight down doors during nose glassing. Nose

top removed to make it easer to work on the rudder peddles and breaks.

Nose

top removed to make it easer to work on the rudder peddles and breaks. Brake

cylinder layout, Matco style. I used aluminum square stock to extend

from F0 the mounting brackets are floxed and bid taped in place.

Brake

cylinder layout, Matco style. I used aluminum square stock to extend

from F0 the mounting brackets are floxed and bid taped in place.  In

this picture you can see the rudder peddles and the stainless steel forks

that I purchased from Dale Rogers. I first saw this design on Brian DeFords

Cozy.

In

this picture you can see the rudder peddles and the stainless steel forks

that I purchased from Dale Rogers. I first saw this design on Brian DeFords

Cozy.  The

Matco master cylinders are now laying on their sides to make it easer to

connect to the reservoir.

The

Matco master cylinders are now laying on their sides to make it easer to

connect to the reservoir. With

this set up I get more than the required peddle travel.

With

this set up I get more than the required peddle travel. Glassed

inside top of the nose, the two small foam block in each side of the opening

is where the locking bars for the doors contact.

Glassed

inside top of the nose, the two small foam block in each side of the opening

is where the locking bars for the doors contact. Nose

re-attached with flox and bid tape inside and out.

Nose

re-attached with flox and bid tape inside and out. Glassed

the canard nose area with two ply of bid and flox corners all around. The

dark green spots are the rudder peddle hard points.

Glassed

the canard nose area with two ply of bid and flox corners all around. The

dark green spots are the rudder peddle hard points. I

wanted to lock the nose access door rather then using screws as called for

in the plans, here is what I came up with, works good.

I

wanted to lock the nose access door rather then using screws as called for

in the plans, here is what I came up with, works good. Purchased

two keyed alike barrel locks one for the nose and the second on will be used

to open the cockpit.

Purchased

two keyed alike barrel locks one for the nose and the second on will be used

to open the cockpit. Here

is the locking mechanism I created for the main nose access door, showing

the locked position. The aluminum bar extend to catch the underside of the

nose compartment.

Here

is the locking mechanism I created for the main nose access door, showing

the locked position. The aluminum bar extend to catch the underside of the

nose compartment.  In

this picture the locking mechanism is in the open position, the bars retract

in the 90 degree turn of the key, works real smooth and holds the doors down

nice the tight.

In

this picture the locking mechanism is in the open position, the bars retract

in the 90 degree turn of the key, works real smooth and holds the doors down

nice the tight.  Landing

gear doors material outside glassed, the center line is where I will cut the

doors apart after installed on the hinges.

Landing

gear doors material outside glassed, the center line is where I will cut the

doors apart after installed on the hinges. Nose

wheel doors with hinges glassed, removed excess foam for landing gear wheel

and strut.

Nose

wheel doors with hinges glassed, removed excess foam for landing gear wheel

and strut. The

spring on the right hand side is used to close the doors when the landing

gear is retracted, got this idea from other buildings. Thanks

The

spring on the right hand side is used to close the doors when the landing

gear is retracted, got this idea from other buildings. Thanks Two

strips of ply wood floxed in place with 5 threaded aluminum slugs on each

side. Ends of door opening floxed and glassed.

Two

strips of ply wood floxed in place with 5 threaded aluminum slugs on each

side. Ends of door opening floxed and glassed. Floxed

doors in place weighted down.

Floxed

doors in place weighted down. Testing

landing gear doors, the spring works great.

Testing

landing gear doors, the spring works great. Wheel

well installed with flox and bid.

Wheel

well installed with flox and bid. Return

spring mount for rudder peddle, one on each side.

Return

spring mount for rudder peddle, one on each side.