Started 12/20/2004 finished 03/13/2005 Hours worked this

chapter. 60.0 hours

No

power controller, just two

battery charger do the job and cost a lot less. For some time I was thinking

about buying the power transformer but than I thought what would I do with

it after. I can always use battery charges ($39.00 on sale at Sears)

No

power controller, just two

battery charger do the job and cost a lot less. For some time I was thinking

about buying the power transformer but than I thought what would I do with

it after. I can always use battery charges ($39.00 on sale at Sears)

Here is my hot wire saw. It's easy to handle, made from 1/4 plywood and some

1 X 4 , 2 X 4 about 3 lbs.

Here is my hot wire saw. It's easy to handle, made from 1/4 plywood and some

1 X 4 , 2 X 4 about 3 lbs.

The following are the center canard core. For the first time

it came out good. It was a lot of fun to see the core change from a one

dimensional template to a real 3D wing part.

One

thing I did do is go over the temples and make

sure the edges are as smooth as I can get them, the hot wire will catch on

the smallest bumps. (Take your time on the templates!!)

One

thing I did do is go over the temples and make

sure the edges are as smooth as I can get them, the hot wire will catch on

the smallest bumps. (Take your time on the templates!!)

The outboard foam is on back order, should be here in a week.

The outboard foam is on back order, should be here in a week.

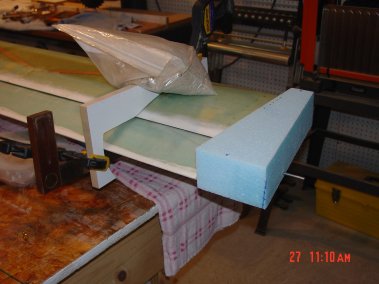

Once all the cores are hot wired and the leading edge is cut off, you put in the dowel pins as call for, this

will make putting the leading edge back on a snap.

After the cores are cut

leading edge removed, the three part are epoxy together

then put into the jig you see in this picture.

After the cores are cut

leading edge removed, the three part are epoxy together

then put into the jig you see in this picture.

Next is the leading edge set up for the bottom spar cap. You can see the

dowels that hold the parts in their original locations.

Here you can see the tabs that are used to bolt the canard to the fuselage.

Use the gauge templates often to make sure you've got the canard just right.

NOTES: Make sure that the top and bottom gauge templates come together on

both leading edge and trailing edge. Sand carefully until they do.... don't

forget the thickness of the glass it will make the canard bigger so leave

room for it.

Here you can see the tabs that are used to bolt the canard to the fuselage.

Use the gauge templates often to make sure you've got the canard just right.

NOTES: Make sure that the top and bottom gauge templates come together on

both leading edge and trailing edge. Sand carefully until they do.... don't

forget the thickness of the glass it will make the canard bigger so leave

room for it.

In

this picture you can see the dowels used to re-align the leading edge with

the rest of the canard.

In

this picture you can see the dowels used to re-align the leading edge with

the rest of the canard.

Leading edge almost ready to be attached just some foam needs to be removed

at the tab location.

Leading edge almost ready to be attached just some foam needs to be removed

at the tab location.

Here

you see the laser I used the make sure all was lined up correctly before the

bottom spar cap work.

Here

you see the laser I used the make sure all was lined up correctly before the

bottom spar cap work.

The

canard spar and leading edge joint are filled with macro and the surface is

smoothed making sure all joints are true and level. Make sure the gauge

templates are used often.

The

canard spar and leading edge joint are filled with macro and the surface is

smoothed making sure all joints are true and level. Make sure the gauge

templates are used often.

You can see the spar tap jig I made to help hold it when putting it down on

the canard.

You can see the spar tap jig I made to help hold it when putting it down on

the canard.

The canard is covered with cut up garbage bags so that the epoxy goes where

I want and no where else. Bottom spar cap complete.

The canard is covered with cut up garbage bags so that the epoxy goes where

I want and no where else. Bottom spar cap complete.

Bottom

canard glassed next put the canard on the blocks of wood and PVC pipe to

finish the top spar, hard points, antenna and skin.

Bottom

canard glassed next put the canard on the blocks of wood and PVC pipe to

finish the top spar, hard points, antenna and skin.

Here

you can see the hinge hard points not yet sanded level. The Fish tail has

been cut off and the canard profile is set to match the template.

Here

you can see the hinge hard points not yet sanded level. The Fish tail has

been cut off and the canard profile is set to match the template.

This

is a shot of the finished prep top.

This

is a shot of the finished prep top.

On

the top I've put the GS was 7.5" and the Nav was 22.8". The cable is put

into a channel just big enough but not to big, I wanted the cable to be

pushed into the channel and not pop up during glassing.

On

the top I've put the GS was 7.5" and the Nav was 22.8". The cable is put

into a channel just big enough but not to big, I wanted the cable to be

pushed into the channel and not pop up during glassing.

Leading

edge glass rolled around onto the bottom skin making for a smooth

transition.

Leading

edge glass rolled around onto the bottom skin making for a smooth

transition.

At

this end of the canard you can see the sanded 1 inch area where the wing tip

glass will go.

At

this end of the canard you can see the sanded 1 inch area where the wing tip

glass will go.

Block

of foam macro to the end, elevator hinge pin rod sticking out.

Block

of foam macro to the end, elevator hinge pin rod sticking out.

Set

zero angle used to a-line the wing tip template.

Set

zero angle used to a-line the wing tip template.

I

used a wood glue bottle with sand paper sprayed glued to it as a sanding

form

for the curve in the canard wind tip. Also you can see the blue template

line on the foam set at zero elevator angle.

I

used a wood glue bottle with sand paper sprayed glued to it as a sanding

form

for the curve in the canard wind tip. Also you can see the blue template

line on the foam set at zero elevator angle.

The

top glass was nothing heard to do, the only part was where to stop when

going around the end and heading to the trailing edge.

The

top glass was nothing heard to do, the only part was where to stop when

going around the end and heading to the trailing edge.

Next

step is to knife trim and sand the bottom contour.

Next

step is to knife trim and sand the bottom contour.

The

black oval on the tip is where the hinge rod comes through. Here I used a

straw as the liner for the hole.

The

black oval on the tip is where the hinge rod comes through. Here I used a

straw as the liner for the hole.

The

trailing edge gets a filling of macro, after cure sanding completes the tips.

The

trailing edge gets a filling of macro, after cure sanding completes the tips.

On to Chapter 11