Working on the interior while it is easy to lay the fuselage

on its side.

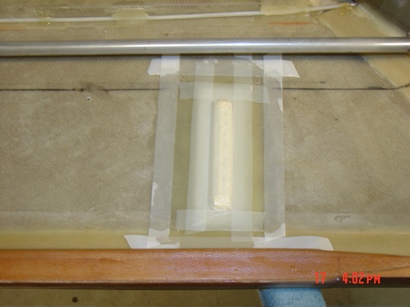

Glassing

cover for the speed brake linear actuator. See more about the installation

of the actuator in Chap 9.

Glassed

in the cover with packing tap on fuselage for release, used screws to make

it removable.

Glassing

the back center consol foam

Glass

the front center consol foam

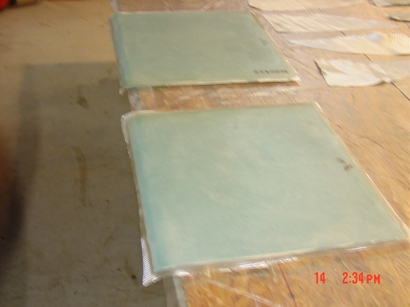

Creating

map pocket using two ply of bid, this lay up is cut in two for each armrest

map packets.

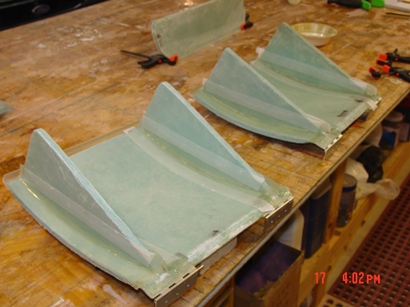

Glassing

the seat leg support parts

Also

in these pictures you can see the plastic on the workbench, it's cut up

garbage bags.

Glassing

the backseat backs, fronts and leg support parts.

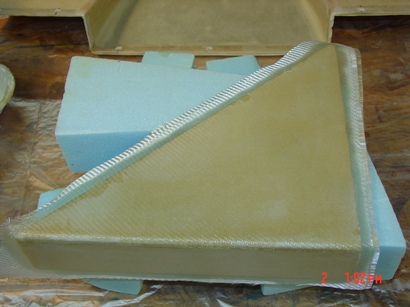

Glassing

the backseat bulkheads

Glassing

the bottom of the front seat before mounts to the supports to get the proper

cure.

Test

fit the armrest foam over the installed map packet. The foam is glued up

using 5 minute epoxy.

Adding

hard points for the back seats hinges that get pop rivets in the bottom of

the fuselage. Due to the other hard points only one more needed to be added,

the others where from the seat belt hard points.

Floxed

the edges of the back seat, used a 1/2 sanding tool to remove the foam came

out real nice and clean.

Test

fit and glued up the foam part for the back seat armrest.

Installed

the fuel site gauge, I will also install fuel probes as the primary with

these as a backup.

Here

you can see how I shaped the underside of the fairing. I hot glued 36 grit

sand paper, then I slid the block of foam back and forth until the shape of

the canard was just right. To complete the underside I glued two more

strips of foam at the back f28 and just in front of the canard leading edge.

Here

you can see how I shaped the underside of the fairing. I hot glued 36 grit

sand paper, then I slid the block of foam back and forth until the shape of

the canard was just right. To complete the underside I glued two more

strips of foam at the back f28 and just in front of the canard leading edge.

Shaping

the foam, used a block of scrap foam to smooth and fine tune the shape.

Every time I do this I tell myself that this foam will be strong when the

glass is added. When Nat say no special tools required he mean it.

Glassing

the canard fairing

Building

the leading edge of fuel cell.

Adding

the filler for the surface between the wing root and fuel cell.

Leading

edge work on the bottom.

Shined a light through the glass so I can see the location of the tire.

Pants for the co-pilot side, cut out for wheel on half of the part.

As you can see this is a molded part I getting it ready to test fit.

Inside half that will be mounted to the landing leg.

Leg fairing glassing flange added for mounting nut plates and screws.

Cut the wheel opening added sticks at the joint of the two halves that helps

alien

the joints

Glassing the flange for mount plates.

In this picture you see how shinny the pants are, will need to sand before

macro fill.

Glassing a flange for the mounting plates, this will allow me to take this

off the leg if required.

Assembled, starting the macro fill. Garbage bags used to keep the part

separate.

Next step is sanding and more sanding.

More to come